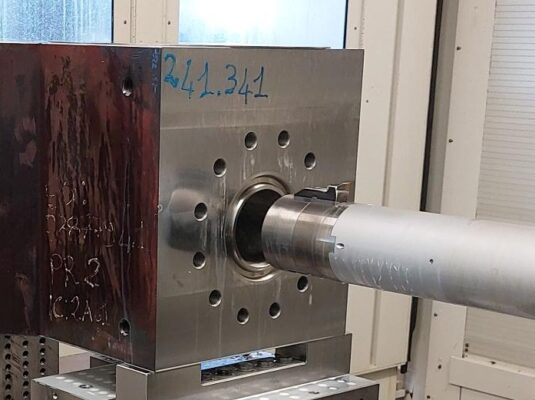

CNC Precision Milling

Milling allows a component to be modelled through the progressive removal of material until the requested geometry is achieved. The equipment used is called milling machine: it is very versatile and capable of carrying out a wide variety of operations. Let’s find out more!

The types of machining that can be carried out with the milling machine ranges from shaping, rolling and finishing of mechanical components to the creation of grooves, seats (with special equipment), chamfers, holes and threads.

How does it work?

In the past, operations with the milling machine were carried out manually, but thanks to modern computerized numerical control machines, it is possible to program all operations and carry them out automatically.

The CNC milling machine consists of a motor spindle, which mounts and rotates the milling cutter, and an alternating adjustable worktable that moves the part.

The production of the component goes through two fundamental phases: during the first one, called rough machining, the material is removed quickly and roughly. This is followed by a finish machining phase in which the milling cutter works on the part to give maximum definition even if very tight tolerances are needed.

The components that can be produced with the aid of the CNC milling machine have applications in many sectors, including mechanical engineering, shipbuilding and petrochemical sectors.

What are the advantages of using a CNC milling machine?

Milling requires a very high degree of precision, especially when producing complex parts. Thanks to the computerized work of the machine, it is possible to produce very precise components that are totally in line with the customer’s requirements.

Let’s take a look at the advantages of the CNC milling machine over the manual one:

1. It guarantees higher precision and accuracy;

2. It can achieve high production speeds;

3. Costs and delivery times of finished products are significantly reduced;

4. The versatility of the CNC milling machine allows different types of machining to be carried out on the same machine;

5. Tolerances on the finished part is down to a few hundredths of a millimeter and the margin of error is reduced to a minimum.

6. The CNC milling machine is safe because it is equipped with a fully enclosed safety guard with sliding doors.

7. The entire machining process is 100% automatic.

Do you want to find out more about the CNC machines we use or ask for a quotation?

Contact us at sales @covisgroup.it