The feasibility analysis of a mechanical component

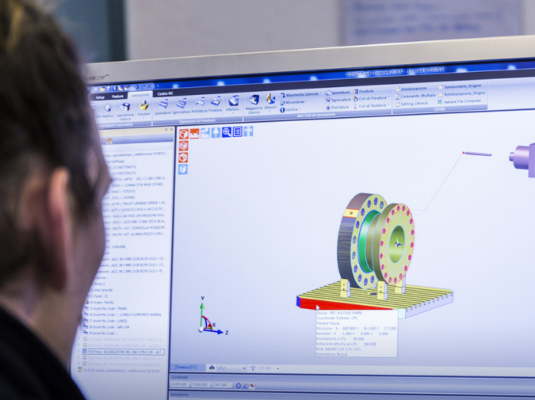

The manufacturing process of a mechanical component begins with the drawing in which the abstract idea is graphically represented using specific CAD software.

But if the design starts from the drawing, it is only during the feasibility analysis that all the characteristics of the finished product and its production process are definitively determined. In this phase, there are numerous decisions to be made and they can profoundly affect the performance of the finished product.

This is why relying on an expert and specialized partner in custom machining such as Covis Group is so important: project success is at stake.

The crucial phase of the feasibility analysis

The first objective of the feasibility analysis is to verify that the component is operationally feasible and that there are no technical impediments to its production.

Secondly, the evaluation of the mechanical drawing presented by the customer also is necessary to define the types of processing required, the surface treatments, the characteristics of the materials used, and their conformity to the context in which the component will be used.

All the choices made during the feasibility analysis flow into a detailed estimate to be submitted to the customer, which, once agreed upon, turns into an order.

At this point, our project managers proceed with the organization and planning of the work, constantly taking into consideration the customer’s needs both from a technical point of view and in terms of costs and production times.

Covis Group and personalized consultancy

During the design of the component and its feasibility analysis, our collaborators are always available for direct discussion with customers, because this can mean a better understanding of their needs and a more careful choice of materials and processes. In some cases, working closely with the customer is essential to obtain the best workability of the material.

As a partner specialized in custom mechanical machining, Covis Group can advise designers on the most suitable materials for each area of application and the recommended surface treatments. We make our many years of experience available to work in synergy with our customers and produce tailor-made solutions with high-quality standards.

Furthermore, especially in the carpentry and large steel machining sectors, our technical office can make the most appropriate improvements to the mechanical drawing provided by the customer to make the manufacturing process more efficient, and in compliance with the project requirements.

Are you looking for a partner able to produce precision mechanical components based on drawings? Contact us at sales.covis@covisgroup.it